Around the world, 150 billion cubic meters of associated gas are flared and vented every year. This has a significant impact on the environment as 400 million tons of carbon dioxide are emitted. Destinus Energy can utilize even highly contaminated and low- calorific gases as fuel to generate clean electricity.

Oil & Gas Solution

Flexible In Fuel & Reliable In Operation

Why it's unique

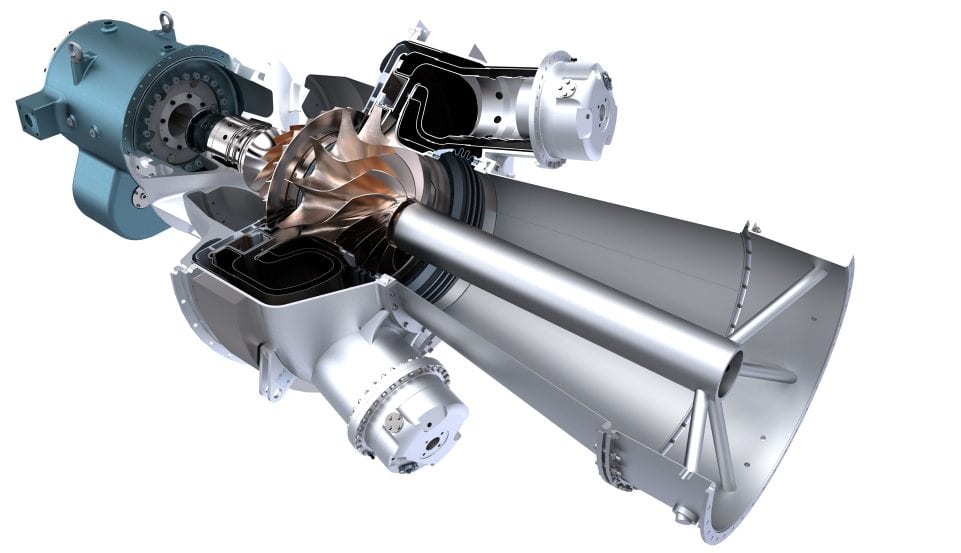

The OPRA OP16 Gas Turbine enables...

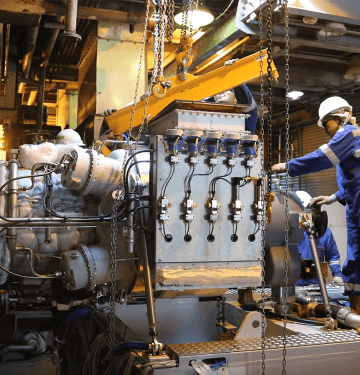

- Compact and reliable design

- Ability to tolerate high H2S content in the fuel

- Ability to operate on flare gas

- 40,000 operating hours between overhauls

- Proven track record

- Successful certifications (DNV, API, GOST)

Success Stories

Read how the OPRA OP16 Gas Turbines are used

The OPRA OP16 Gas Turbine can run on almost any gas or liquid fuel

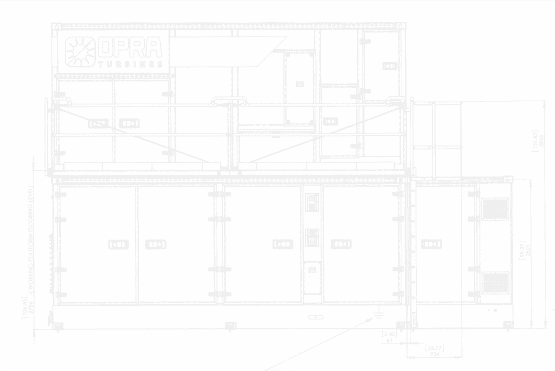

System integration

Destinus Energy expertise

To ease the process of integrating the OPRA OP16 Gas Turbine into your current or new application, Destinus Energy can assist by providing process know-how and knowledge of best practice. Are you looking for a turnkey solution? We work with an international network of Oil & Gas partners who are experts in integrating our equipment into existing or new plants.